C40 POWEVER Sectional Door Operator

- Category: Industrial Sectional Door Motor

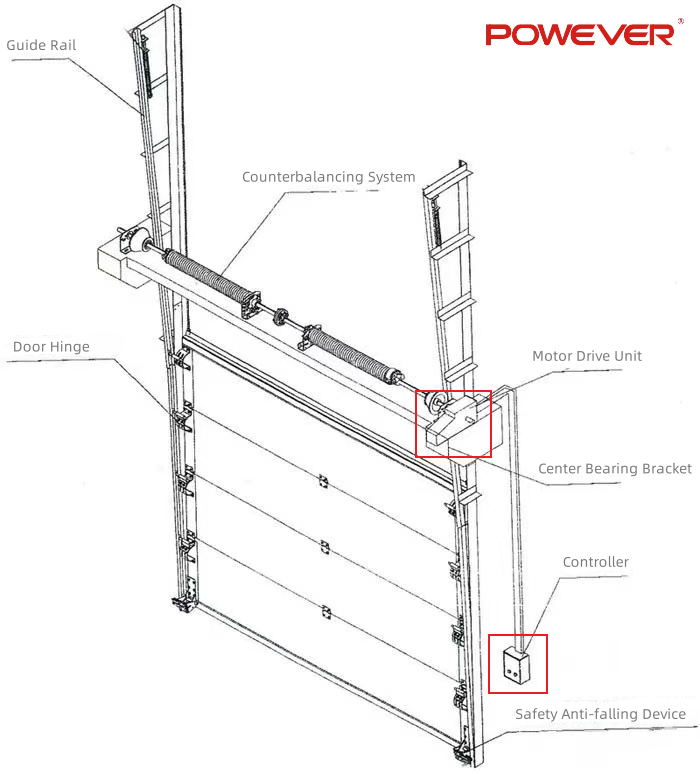

POWEVER C Series is a dedicated drive operator for sectional doors with a counterbalancing system. Its motor drive unit is typically mounted directly on the shaft. C Series motor drive unit consists of servo motor, motor driver, worm gear reducer, emergency manual operating override (hand chain), electric/manual gear selector (optional), and cables. C Series offers a maximum output speed of 50 rpm and a variety of output torque options: 25 N.m, 35 N.m, 40 N.m, 60 N.m, 90 N.m, 120 N.m, and 500 N.m.

The limit can be easily set by using the built-in incremental encoder or absolute encoder. C Series servo motor is equipped with a high-precision encoder and utilizes a closed-loop vector control algorithm, it precisely monitors and controls output speed and torque, ensuring the smooth and accurate door operation. The accompanying controller's LCD display displays operating status: speed, torque, and door position. Thanks to the servo motor's instant feedback, all motor functions can be adjusted by the user through the controller.

C Series is standardly equipped with practical functions such as soft start and soft stop, rebound/stop when encountering obstacles, and travel adjustment in the acceleration range and deceleration range, which can effectively prevent sudden impacts and significantly extend the service life of the door body.

C Series is suitable for all locations where sectional doors can be used

1. Logistics, warehousing, and sorting centers

2. Food and pharmaceutical industries

3. Manufacturing and automotive factories

4. Other special applications

What POWEVER C Series provide are the Motor Drive Unit and the the Controller.

|

Motor Drive Unit |

|

|

MOTOR TYPE |

Servo Motor |

|

WORKING SYSTEM |

S3 |

|

POWER |

450 W |

|

POWER SUPPLY |

1N- 220 V ± 10% |

|

FREQUENCY |

50 ~ 60 Hz |

|

OUTPUT SPEED |

Max 50 rpm (Rated Max 30 rpm) |

|

OUTPUT TORQUE |

40 N.m |

|

MAX DOOR WEIGHT |

320 kg |

|

SOFT START AND SOFT STOP |

Yes |

|

MOTOR IP LEVEL |

IP54 |

|

WORKING ENVIRONMENT |

20 ~ + 50 ℃ |

|

OUTPUT APERTURE |

25.4 mm |

|

INCREMENTAL ENCODER |

Yes |

|

ABSOLUTE ENCODER |

Yes |

|

LENGTH OF HAND CHAIN |

4 m |

|

LENGTH OF CABLES |

5 m |

|

DOOR OPERATING SPEED |

Adjustable |

|

RECOMMENDED RUNNING TIMES PER HOUR |

10 times |

|

WEIGHT |

10 kg |

|

CONTROLLER |

||

|

MODEL NO. |

DW4 |

DW5 |

|

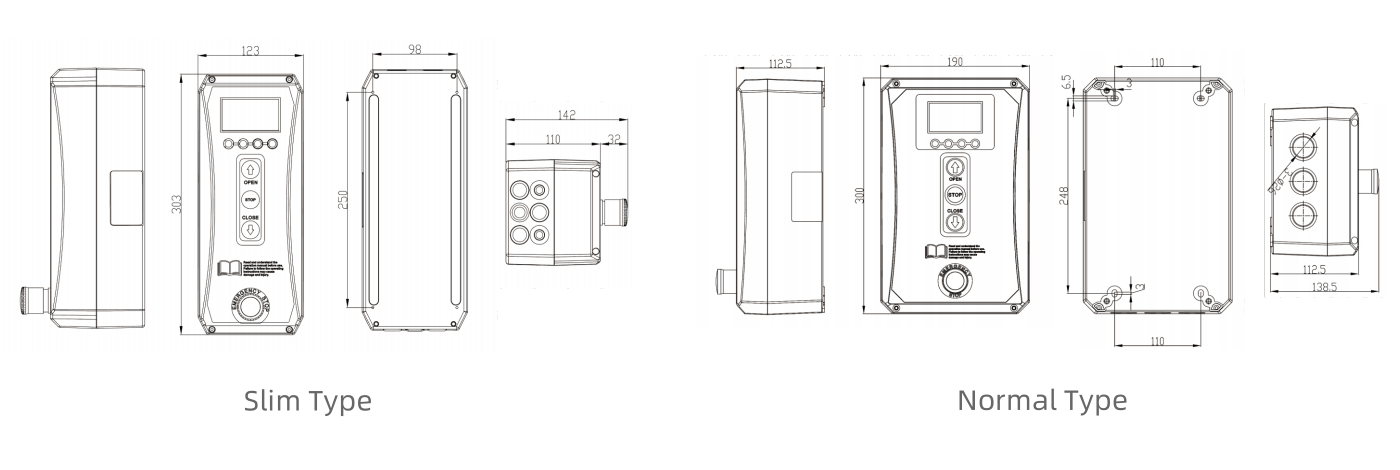

DIMENSION |

Normal: 190*138.5*300 mm; Slim: 123*142*303 mm |

|

|

DISPLAY SCREEN |

3-inch LCD screen (4 lines of text display) |

|

|

SOFT START AND SOFT STOP |

Yes |

|

|

SELF-CHECK AND TEST |

Yes |

|

|

PROACTIVE MAINTENANCE REMINDER |

Yes |

|

|

REBOUND/STOP WHEN ENCOUNTERING OBSTACLES |

Yes |

|

|

MULTIPLE OPERATING METHODS |

Auto/Jog/Hand chain |

|

|

DOOR OPERATING SPEED |

Adjustable |

|

|

ACCELERATION RANGE AND DECELERATION RANGE |

Adjustable |

|

|

AUTOMATIC CLOSING DELAY |

1 - 240 seconds |

|

|

SAFTY HEIGHT |

Adjustable |

|

|

SERVO INFORMATION DISPLAY |

Torque/Speed/Position |

|

|

FAULT PROMPT |

Yes |

|

|

HISTORICAL FAULT QUERY |

Yes |

|

|

INPUT PORT STATUS QUERY |

Yes |

|

|

AUTOMATIC ANTI-FREEZING OPERATING |

Yes |

|

|

INTERFACE CONTACT TYPES SWITCHING (NO/NC) |

Yes |

|

|

OPEN/STOP/CLOSE SIGNAL INPUT |

Yes |

|

|

EMERGENCY STOP INPUT |

Yes |

|

|

PEDESTRIAN DOOR |

Yes |

|

|

SAFETY SIGNAL INPUT |

Rebound/Stop |

|

|

RELAY OUTPUT |

2 groups |

2 or 4 groups |

|

MULTIFUNCTIONAL PORT |

1 group |

4 groups |

|

12V POWER SUPPLY PORT |

1 |

3 |

|

REMOTE CONTROL |

Yes |

|

|

RS485 |

No |

Yes |

|

WEIGHT |

Normal: 2 kg; Slim: 1 kg |

|

ACCURATE

Full closed-loop servo control of position, speed and torque is realized, and high accuracy electronic limit is adopted to avoid exceeding limit at long-term running. The operator does not need to climb up to set the limits, which greatly ensures the safety of personnel.

STABLE

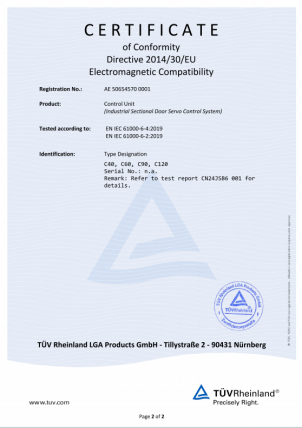

Excellent Integrated design and EMI/EMC design ensures the full closed-loop control and real-time detection of motor output data, through this function can detect the torsion spring, tension spring and other balance system working state, detect the door body stuck point position.

EFFICIENT

The rated output speed of the high-speed door servo system and the industry sectional door servo system are 133 rpm and 40 rpm, and the maximum running speed are 1.95 m/s and speed is 0.4 m/s separately.

SMOOTH

Adopting high accuracy servo control technology to make the whole running state of the door body smooth without jitter, which helps to reduce the impact on the mechanical structure of the door body and lead to structural failure, and greatly extend the service life of the door body.

VISUAL

LCD monitor can display parameters and fault information, brings excellent interactive experience to users, allow them to debug and maintain easily without professional help.

SAFE

The system comes with multiple protection methods such as over-voltage, under-voltage, over-current, short-circuit, encounter resistance, etc., emergency signal response time is less than 30 milliseconds, to maximize the protection of people and things safe passage.

FREQUENT

The high-speed door servo system has been tested continuously for 1,000,000 times without interruption (the test runs continuously at a 10 seconds switching frequency). It’s Ideal for ultra-frequent fast pass environments.

ENERGY SAVING

The system uses AC PMSM motor, which adopts rare earth permanent magnet material. The efficiency is doubled compared with the traditional induction motor, and it has the advantages such as energy-saving, light weight, low temperature rising, large torque and twice overload, etc.

CATEGORIES

LATEST NEWS

CONTACT US

Name: Peter

Mobile:+86 18602730822

Tel:+86 18602730822

Whatsapp:+86 18602730822

Email:peter.zhou@powever.com.cn

Name: Lea

Mobile:+86 15926413664

Tel:+86 15926413664

Whatsapp:+86 15926413664

Email:lea@powever.com.cn

Add:R&D center : 5th floor,Building A1,Wuhan University Science Park, Wuhan, Hubei Province, China

Factory Add:Building C, Wuhan Inland Port Center, No. 100 Hanshi Highway, Xinzhou District, Wuhan, Hubei Province, China